High pressure leaks cause extensive damage to adjacent components

Normal detection methods (manual inspection, makeup water use, temperature monitoring) can only find leaks of significant size that are already causing major damage

Undetected leaks can cause unexpected downtimes

Downtime cost can be significant, based on:

the number of tubes needing repaired

the types of repairs needed

the amount of outage hours the unit is off-line and unavailable

Downtime at peak hours incurs high replacement power costs (sometimes exceed ing $100,000 per day)

The Need:

Early detection of high pressure leaks so that damage is controlled

Advanced notice of leak problems to minimize costs due to damage

Controllable downtimes for repairs to lower power replacement costs

The Solution:

ALL™ is a leak detection and warning system designed for on-line monitoring of pressurized systems and valves

ALL™ tells you that problems are developing before the situation becomes serious

ALL™ provides the detailed data needed to make decisions–whether to make immediate repairs or simply schedule future maintenance at an opportune time

The Benefits of ALL™:

Significant Cost Savings–usually pays for itself after just one leak

Vital early warnings

Accurate leak location

ALL™ can detect leaks as small as 5 mils–long before make-up water warnings

Acoustic Leak Locator for Utilities

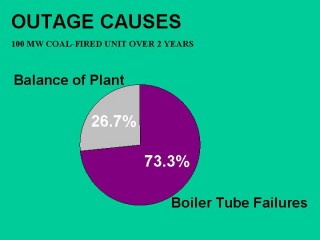

The Problem:

The Need:

The Solution:

The Benefits of ALL™:

Learn how ALL™ detects leaks in your boilers and high-pressure vessels

Read a case study on how ALL™ works in a utility boiler much like yours